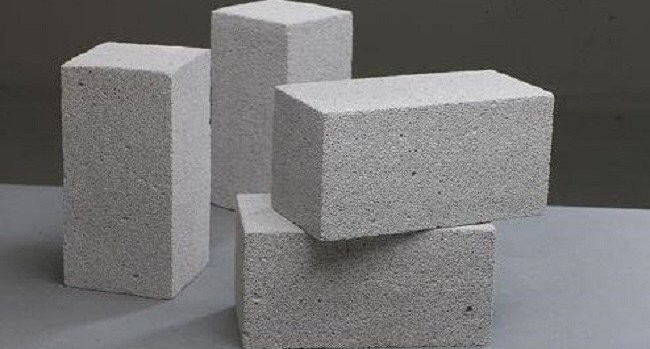

Global Polymer Concrete market size was USD 726.21 million in 2023 and the market is projected to touch USD 1,262.87 million by 2032, at a CAGR of 6.34% during the forecast period. Polymer Concrete combines materials such as sand and gravel with a polymer resin to create a highly durable and versatile construction material. Polymer concrete is rapidly being used in a variety of applications, including industrial flooring, drainage systems, and structural repairs, due to its improved features like as stronger strength, greater chemical resistance, and faster cure times.

The global polymer concrete market has grown significantly, owing to its advantages over traditional concrete. Rising building activity, increased demand for high-performance materials, and the necessity for rapid infrastructure development are driving this expansion. Furthermore, the industry benefits from improvements in polymer technology, which make polymer concrete more cost-effective and accessible.

Global Polymer Concrete report scope and segmentation.

| Report Attribute | Details |

| Base Year | 2023 |

| Forecast Years | 2024 – 2032 |

| Estimated Market Value (2023) | USD 726.21 Million |

| Projected Market Value (2032) | USD 1,262.87 Million |

| Segments Covered | By Type, By Class, By Application, By End-Use, & By Region. |

| Forecast Units | Value (USD Million or Billion) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2024 to 2032. |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Australia, Brazil, Argentina, GCC Countries, and South Africa, among others. |

Global Polymer Concrete dynamics

One of the key factors is the growing demand for high-performance construction materials that are more durable and resistant to chemicals, water, and extreme weather. This makes polymer concrete a desirable material for infrastructure projects, industrial flooring, and repair and maintenance applications. Furthermore, the growing rate of urbanization and industrialization, particularly in emerging nations, is increasing the demand for strong construction materials that can support large-scale developments and extend the life of buildings.

In contrast, the market confronts constraints like as the high cost of polymer resins compared to traditional cement, which might limit their adoption in cost-sensitive projects. Moreover, the production process of polymer concrete requires specialized equipment and skilled labor, potentially increasing the overall construction costs. However, ongoing research and technological advancements are expected to reduce these costs over time, making polymer concrete more competitive. Environmental concerns and the push for sustainable construction practices are also influencing market dynamics, as polymer concrete can be designed to incorporate recycled materials, thus reducing its environmental footprint.

Global Polymer Concrete drivers

Increasing Demand for High-Performance Construction Materials

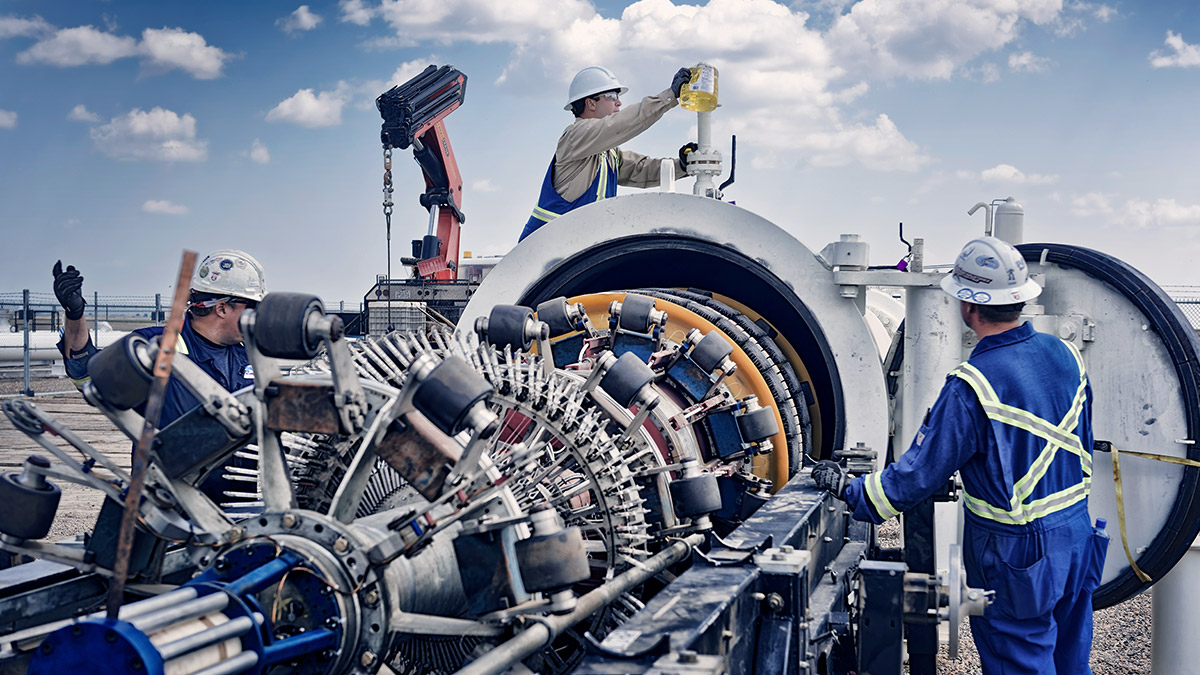

The demand for construction materials with improved durability and performance is a major driver of the polymer concrete industry. Traditional concrete, while widely used, frequently falls short in areas requiring strong resilience to chemicals, abrasion, and extreme weather. Polymer concrete, with its improved qualities such as better compressive strength, shorter curing times, and increased resistance to corrosive chemicals, is becoming more popular in industrial and infrastructural applications. These projects include wastewater treatment plants, chemical containment areas, and heavy-duty industrial flooring, where typical materials would degrade faster. As businesses and infrastructure projects seek materials that can extend the lifespan of their constructions while decreasing maintenance costs, the market for polymer concrete is likely to expand.

Rapid Urbanization and Industrialization

The global trend of increased urbanization and industrialization, particularly in emerging economies, is another important driver of the polymer concrete industry. Urban infrastructure projects in Asia-Pacific, Latin America, and the Middle East are rapidly expanding, involving the development of highways, bridges, commercial buildings, and residential complexes. These large-scale projects necessitate materials that can handle huge loads and extreme weather conditions, which makes polymer concrete an excellent choice. Furthermore, industrial growth requires the use of materials capable of supporting the building of lasting and resistant infrastructure. This urban and industrial expansion creates a consistent need for improved construction materials, thereby fuelling the growth of the polymer concrete market.

- Restraints:

High Cost of Polymer Resins

One of the key limitations to the polymer concrete business is the high cost of polymer resins when compared to regular cement. These resins, which serve as binders in polymer concrete, are more expensive to manufacture and purchase. This cost aspect may make polymer concrete less tempting for cost-sensitive projects, particularly in areas where budget constraints are a significant problem. While the advantages of polymer concrete in terms of durability and performance may justify the larger initial investment, the upfront costs might still be a hindrance to wider adoption, particularly in emerging areas where traditional concrete remains the go-to alternative.

Specialized Production and Skilled Labor Requirements

Polymer concrete manufacture and application require specialized equipment and expert staff, which can make widespread adoption difficult. Unlike ordinary concrete, which can be mixed and poured with standard construction equipment, polymer concrete requires precise mixing ratios and application procedures to attain superior qualities. This necessity for specialist knowledge and equipment might raise the entire cost of polymer concrete building projects, limiting its utilization to firms and projects with the appropriate experience and resources. As a result, this can hinder the expansion of the polymer concrete market, especially in countries where access to skilled labor and equipment is limited.

- Opportunities:

Technological Advancements and Cost Reduction

Ongoing research and technical improvements represent a substantial opportunity for the polymer concrete market. Polymer chemistry and concrete technology innovations aim to reduce manufacturing costs while enhancing polymer concrete performance. For example, novel formulas including recycled materials or using alternative, less expensive polymer resins are being explored. These developments may make polymer concrete more cost-effective and ecologically benign, increasing its competitiveness against traditional concrete. As these technologies mature and become more generally accepted, they can assist overcome some of the cost-related constraints and drive increased market adoption.

- Segment Overview

The polymer concrete market is divided into several types, including epoxy, latex, acrylate, polyester, vinyl, furan, and others. Each form of polymer concrete has distinct characteristics and applications. Epoxy polymer concrete is extremely durable and chemically resistant, making it ideal for industrial purposes. Latex-modified concrete, which improves flexibility and crack resistance, is commonly used in repair and maintenance. Acrylate polymer concrete is well-known for its fast curing time and adherence, making it perfect for quick repairs and high-traffic areas. Polyester and vinyl polymer concretes are highly appreciated for their strength and resistance to corrosive environments, and are widely employed in maritime and chemical containment applications. Furan polymer concrete is extremely resistant to acids and solvents, making it ideal for tough industrial applications.

Polymer concrete is categorized into three types: polymer modified concrete (PMC), polymer resin concrete (PRC), and polymer impregnated concrete (PIC). PMC is the adding of polymers to standard concrete to improve its qualities, such as tensile strength and durability, which is often used in overlays and repair operations. PRC is fully made up of polymer binder and aggregates, which provide exceptional chemical resistance and mechanical strength, making it perfect for industrial flooring and structural applications. In contrast, PIC includes impregnating pre-cast concrete parts with polymer to increase their long-term viability and against environmental influences. This categorization enables a wide range of applications, each customized to unique performance needs in construction and industrial contexts.

Global Polymer Concrete Overview by Region

North America controls a sizable portion of the market due to its well-established building sector and strong demand for sophisticated materials that provide greater durability and performance. The United States and Canada make significant contributions, with polymer concrete used extensively in infrastructure projects, industrial floors, and maintenance applications. Additionally, rigorous environmental rules and a significant emphasis on sustainable construction methods push the development of polymer concrete in this region.

The market in Europe is driven by the region’s emphasis on high-quality construction materials, as well as the presence of significant polymer concrete manufacturers. Countries such as Germany, the United Kingdom, and France are at the forefront of using polymer concrete for infrastructure enhancements and industrial applications. The region’s emphasis on sustainability and innovation in construction materials also contributes to market growth, as polymer concrete is increasingly used in green building projects and the restoration of old structures.

The Asia-Pacific region is experiencing the fastest growth in the polymer concrete market, driven by growing urbanization, industrialization, and infrastructure development in countries such as China, India, and Japan. The demand for durable and high-performance construction materials is rising due to large-scale infrastructure projects, including roads, bridges, and commercial buildings. Government initiatives aimed at improving infrastructure and urban facilities further bolster the market, alongside the growing industrial sector which necessitates robust materials for flooring and containment.

Global Polymer Concrete market competitive landscape

BASF SE, Sika AG, Fosroc International Limited, and Mapei S.p.A. are the market’s leading players, owing to their wide product portfolios, strong R&D capabilities, and global distribution networks. These firms prioritize constant innovation to improve the qualities of polymer concrete, making it more durable, cost-effective, and environmentally friendly. Strategic alliances, mergers, and acquisitions are frequent techniques used by these significant competitors to increase market share and broaden their product offerings.

In addition to these established enterprises, the market is witnessing the emergence of other regional and local manufacturers who utilize their awareness of local market needs and cost advantages to compete effectively. These companies often focus on providing customized solutions tailored to specific applications in residential, non-residential, and infrastructure projects. The competitive intensity is heightened by the development of new formulations and technologies that aim to reduce the overall cost of polymer concrete and improve its sustainability profile.

Contact Us:

Mob : +91 9319642100

Noida One Tower Sec 62 Noida 201301

Sales : sales@organicmarketresearch.com

Website : https://www.organicmarketresearch.com